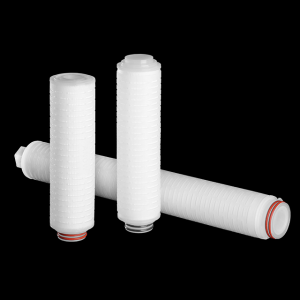

Sterilizing-grade filters for the sterile filtration of gases

Short Description:

Hydrophobic cartridge filters provide high flow rate and minimal differential pressure. Cartridges are robust, strong, and resilient and are designed to withstand multiple steam-in-place cycles. Each cartridge filter is integrity tested during the manufacturing process.

A full range of filtration areas is available to suit varying applications and a variety of connection options are offered for easy adaptation to existing housings.

Key Features

◇ Highly safe sterilization, ensuring 100% filter efficiency in humid environment during gas

filter, 0.2um filter rating in liquid, for gas filter, single layer: < Φ0.01μm; double layer: < 0.003μmΦ;

◇ Strong hydrophobicity, passing water intrusion test, avoiding residues due to the integrity of solvent wetting test;

◇ Single- or double-layer; large filter area, small pressure difference, large throughput, long service life;

◇ Excellent chemical compatibility, endurable to acid, alkali, and organic solvent;

◇ Cartridge independently numbered, production batch traceable;

◇ Passing 100% integrity test, quality safe and reliable;

Typical Applications

◇ Pre-filtering gases of storage tanks, respirators, and ferment tanks sterilization;

◇ Sterilization of solvents such as esters, alcohols, acids, and alkalis particle filtering;

◇ Sterilization and filtering of compressed air or gases in medicine and food industries;

Material Construction

◇ Filter medium: Hydrophobic PTFE

◇ Support/drainage: PP

◇ Core and cage: PP

◇ O-rings: see the cartridge list

◇Seal method: melting

Operating Conditions

◇ Maximum working temperature: 90°C, 0.20 Mpa

◇ Sterilization temperature: 121°C; 30 minutes

◇ Maximum positive pressure difference: 0.42 MPa, 25°C

◇ Maximum negative pressure difference: 0.21 MPa, 25°C

Key Specifications

◇ Removal rating: 0.05, 0.1, 0.2, 0.45, 0.8, 1.0, 3.0, 5.0 (unit: μm)

◇ Effective filter area: single-layered ≥ 0.6 /10″; double-layered: ≥ 0.5 /10″

◇ Outer diameter: 69 mm, 83 mm, 130 mm

Quality Assurance

◇ Passing USP biological reactivity test to class VI plastics

◇ Filtrate: <10 mg per 10 inch cartridge (Φ69)

◇ Endotoxin: < 0.25 EU/ml

◇ Endurable to repeated steam sterilization (more than 50 times) in no-load state