PES (Poly Ether Sulphone) Filter Cartridge

Short Description:

SMS series cartridges are made of imported hydrophilic PES membrane. They have universal chemical compatibility, PH range 3~11. They feature high efficiency, high guarantee, and long service life, applicable to pharmacy, food, chemical industry, electronics, and other fields. Before delivery, each cartridge has experienced 100% integrity test, to ensure product filter efficiency. SMS cartridges are endurable to repeated online steam or high-pressure disinfection.

SMS series cartridges are made of imported hydrophilic PES membrane. They have universal chemical compatibility, PH range 3~11. They feature high efficiency, high guarantee, and long service life, applicable to pharmacy, food, chemical industry, electronics, and other fields. Before delivery, each cartridge has experienced 100% integrity test, to ensure product filter efficiency. SMS cartridges are endurable to repeated online steam or high-pressure disinfection.

Key Features

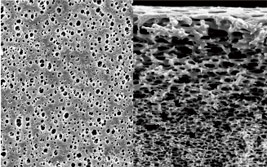

◇ Excellent hydrophile; easy to get wet; absolute pore size, ensuring high removal efficiency;

◇ Symmetric porous distribution, realizing large throughput; electronically neutral feature least absorption, prolonging service life of cartridges;

◇ Single- or double-layer; solid structure; endurable to repeated online sterilization;

◇ Cartridge independently numbered; production batch traceable;

Typical Applications

◇ Pre-filtering and sterilization of biological vaccines, blood products, cell culture solutions, and serums;

◇ Removing bacteria and yeasts out of foods & beverages, beers, wines, and mineral water;

◇ Using as filter of electronic or microelectronic ultrapure water purification systems;

Material Construction

◇ Filter medium: PES

◇ Support/drainage: PP

◇ Core and cage: PP

◇ O-rings: see the cartridge list

◇ Seal method: melting

Operating Conditions

◇ Maximum working temperature: 90°C, 0.20 MPa

◇ Sterilization temperature: 121°C; 30 minutes

◇ Maximum positive pressure difference: 0.40 MPa, 25°C

◇ Maximum negative pressure difference: 0.21 MPa, 25°C

Key Specifications

◇ Removal rating: 0.1, 0.2, 0.45, 0.65, 0.8, 1.2 (unit: μm)

◇ Effective filter area: single-layered ≥ 0.6 /10"; double-layered: ≥ 0.5 /10"

◇ Outer diameter: 69 mm, 83 mm, 130 mm

Quality Assurance

◇ Endotoxin: < 0.25 EU/ml

◇ Filtrate: <30 mg per 10 inch (Φ69)

◇ Biological safety: passing USP biological reactivity test to class VI plastics

◇ Health and safety: passing health and safety test on drinking water

◇ Double-layer cartridges, endurable to repeated steam sterilization (more than 50 times) in no-load state

Ordering Information

SMS--□--◎--◇--○--☆--△

|

□ |

◎ |

☆ |

|

△ |

||||||

|

No. |

Removal rating (μm) |

No. |

Support layer |

No. |

End caps |

No. |

O-rings material |

|||

|

001 |

0.1 |

H |

Single layer |

A |

215/flat |

S |

Silicone rubber |

|||

|

002 |

0.2 |

S |

Double layer |

B |

Both ends flat/both ends passing |

E |

EPDM |

|||

|

004 |

0.45 |

○ |

F |

Both ends flat/one end sealed |

B |

NBR |

||||

|

065 |

0.65 |

No. |

Length |

H |

Inner O-ring/flat |

V |

Fluorine rubber |

|||

|

080 |

0.8 |

5 |

5” |

J |

222 stainless steel liner/flat |

F |

Wrapped fluorine rubber |

|||

|

120 |

1.2 |

1 |

10” |

K |

222 stainless steel liner/fin |

|

|

|||

|

|

|

2 |

20” |

M |

222/flat |

◇ |

||||

|

|

|

3 |

30” |

P |

222/fin |

No. |

Class |

|||

|

|

|

4 |

40” |

Q |

226/fin |

P |

Pharmacy |

|||

|

|

|

|

|

O |

226/flat |

E |

Electronics |

|||

|

|

|

|

|

R |

226 stainless steel liner/fin |

G |

Food and pharmacy |

|||

|

|

|

|

|

W |

226 stainless steel liner/flat |

|

||||