0.22 micron pes membrane pleated filter cartridge used for chemical raw material filtration

Short Description:

NSS series cartridges are made of Micro series hydrophilic asymmetric sulfonated PES. They have universal chemical compatibility, PH range 3~11. They feature large throughput and long service life, applicable to bio-pharmacy and other fields. Before delivery, each cartridge has experienced 100% integrity test, to ensure product filter efficiency. NSS cartridges are endurable to repeated online steam or high-pressure disinfection, meeting asepsis requirements of new version GMP.

Pharmaceutical Grade Polyethersulfone Cartridge

NSS series cartridges are made of Micro series hydrophilic asymmetric sulfonated PES. They have universal chemical compatibility, PH range 3~11. They feature large throughput and long service life, applicable to bio-pharmacy and other fields. Before delivery, each cartridge has experienced 100% integrity test, to ensure product filter efficiency. NSS cartridges are endurable to repeated online steam or high-pressure disinfection, meeting asepsis requirements of new version GMP.

Key Features

◇ Excellent hydrophile; easy to get wet, low protein absorption rate;

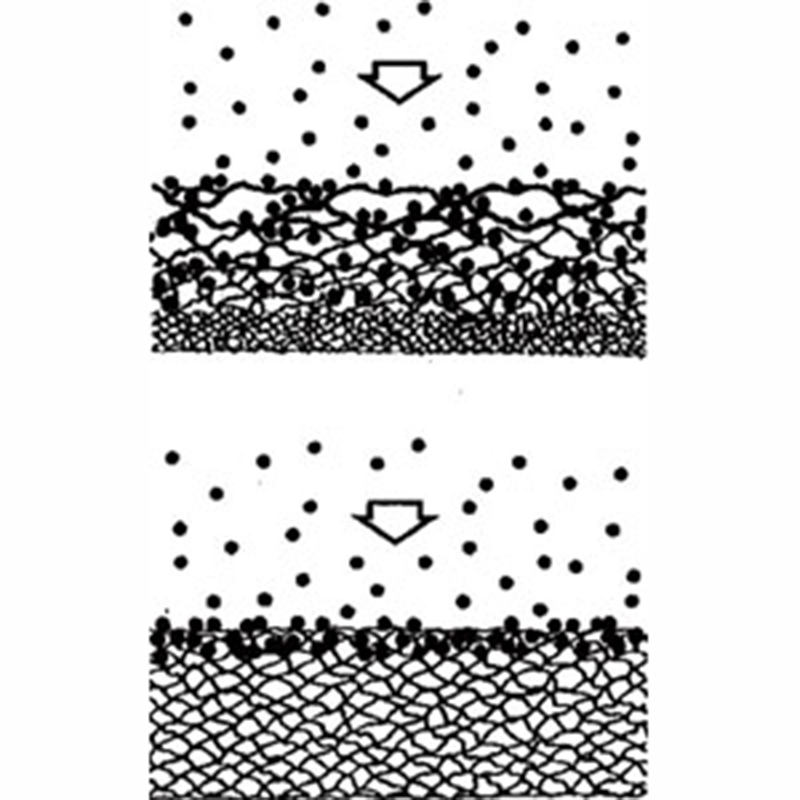

◇ High porosity realized through phase transfer, unique geometric shape, improving passage efficiency and throughput;

◇ Double layer structure use same materials, solid structure; endurable to repeated online sterilization;

◇ Cartridge independently numbered; production batch traceable;

Typical Applications

Pre-filtering and sterilization of biological vaccines, blood

products, cell culture solutions, serums, eye drops, water for

injection, lyophilized products, and liquids to be infused

Material Construction

◇ Filter medium: PES

◇ Support/drainage: PP

◇ Core and cage: PP

◇ O-rings: see the cartridge list

◇ Seal method: melting

Operating Conditions

◇ Maximum working temperature: 90°C, 0.20 Mpa

◇ Sterilization temperature: 121°C; 30 minutes

◇ Maximum positive pressure difference: 0.40 MPa, 25°C

◇ Maximum negative pressure difference: 0.21 MPa, 25°C

Key Specifications

◇ Removal rating: 0.1, 0.2, 0.45, 0.65, 0.8, 1.2, 3.0 (unit: μm)

◇ Effective filter area: single-layered ≥ 0.6 / 10"; double-layered: ≥ 0.5 /10"

◇ Outer diameter: 69 mm, 83 mm, 130 mm

◇ Quality Assurance

◇ Endotoxin: < 0.25 EU/ml

◇ Filtrate: <30 mg per 10 inch (Φ69)

◇ Biological safety: passing USP biological reactivity test to class VI plastics

◇ Health and safety: passing health and safety test on drinking water

◇ Double-layer cartridges, endurable to repeated steam sterilization (more than 50 times)in no-load state

Ordering Information

NSS--□--◎--◇--○--☆--△

|

□ |

◎ |

☆ |

|

△ |

||||||

|

No. |

Removal rating (μm) |

No. |

Support layer |

No. |

End caps |

No. |

O-rings material |

|||

|

010 |

0.1 |

H |

Single layer |

A |

215/flat |

S |

Silicone rubber |

|||

|

002 |

0.2 |

S |

Double layer |

B |

Both ends flat/both ends passing |

E |

EPDM |

|||

|

004 |

0.45 |

○ |

F |

Both ends flat/one end sealed |

B |

NBR |

||||

|

065 |

0.65 |

No. |

Length |

H |

Inner O-ring/flat |

V |

Fluorine rubber |

|||

|

008 |

0.8 |

5 |

5” |

J |

222 stainless steel liner/flat |

F |

Wrapped fluorine rubber |

|||

|

010 |

1.2 |

1 |

10” |

K |

222 stainless steel liner/fin |

|

|

|||

|

030 |

3.0 |

2 |

20” |

M |

222/flat |

◇ |

||||

|

|

|

3 |

30” |

P |

222/fin |

No. |

Class |

|||

|

|

|

4 |

40” |

Q |

226/fin |

P |

Pharmacy |

|||

|

|

|

|

|

O |

226/flat |

E |

Electronics |

|||

|

|

|

|

|

R |

226 stainless steel liner/fin |

G |

Food and pharmacy |

|||

|

|

|

|

|

W |

226 stainless steel liner/flat |

|

||||